Port

Oil

Length

370~400m

Berthing capacity

Port

Length

Berthing capacity

1.There is a need for a solution that enhances the safety of berth workers to prevent serious accidents.

2.There is a need for new technologies to assist in the diverse and complex operational processes within the port.

1.Previously, it was difficult to monitor workers due to the size of the berth. However, with the implementation of AVISS, automatic worker detection and risk alerts have enabled safer management of workers.

2.By providing alerts for various scenarios, such as when a worker enters a specific zone, remains motionless for 10 minutes, or when no worker is detected on the berth for 30 minutes, tasks that were previously manually verified by personnel have been automated. This automation has significantly increased operational convenience and efficiency.

· B Port Operations Company, Team Manager OO

"I am very satisfied with the improvements made to our internal processes, which are significant enough to be integrated into our core operations”

※ This case is based on true events.

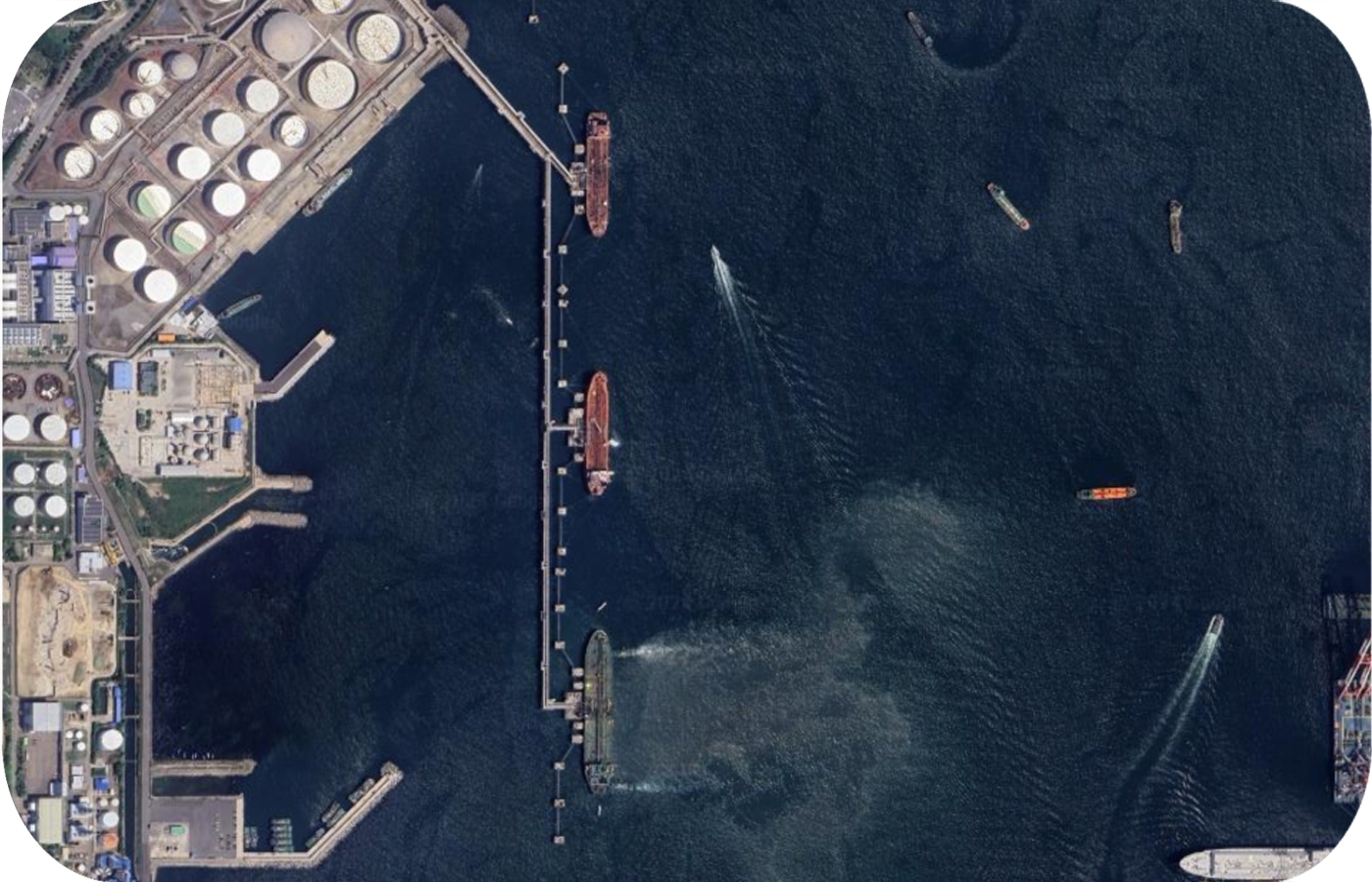

AVISS monitors the surrounding area of berthing ships and provides real-time berthing status data to stakeholders.

In addition, it increases operational efficiency and safety by supplying port operation analytical data from the time of ship arrival to departure.